FAQ of Nano Glass Crystallized Stone Panels

Do you have the questions about Nano glass Crystallized Sonte Panels? Maybe you can find out the answers from here. You can also ask your questions and we will be happy to answer.

- Q1: What products does ZONVE supply?

- Q2: What is Nanoglass?

- Q3: What is the scope of application of nanostones?

- Q4: What are the features of Nanoglass?

- Q5: What are the advantages of nanostone?

- Q6: What is the difference between nano stone and natural stone?

- Q7: What are the advantages of ZONVE?

- Q8: What is 3D printing nanostone?

- Q9: Why can nano stone slabs be used as kitchen countertops?

- Q10: Why can nano stone be used as wall and floor covering material?

What products does ZONVE supply?

Factory Direct, Competitive Price

- Nano Crystallized Glass Stone Slab specular gloss over 95 degrees

-- Pure white slab and super black slab

-- Size: 2800x1600, 3200x1600, 3000x1500mm

-- Thickness: 12mm, 18mm, 30mm

-- Size and thickness can be customized

- 3D Inkjet Pringting NanGlass Stone Panels

-- Size: maximum width 1600mm

-- Thickness: 12mm, 18mm.

-- The pattern can be customized according the drawing

- Nanoglass Countertops

-- The size and shape can be customized according the order requirements.

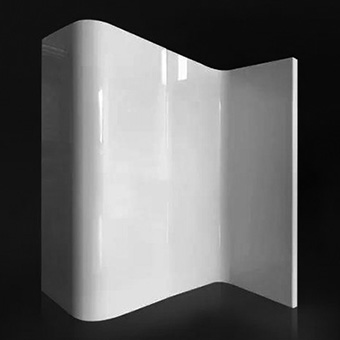

-- Hot bending, special-shaped, etc.

What is Nanoglass?

Nanoglass main element is Silicon Dioxide – SiO2. Nanoglass also called Nano Crystallized Glass, Pure White Nanoglass, Neoparies, Artificial White Marble, Glass Stone.|

Fabrication of Nano Glass

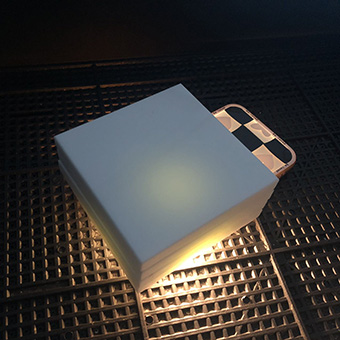

Nano glass is manufactured from a blend of natural materials that is 75 percent silica and 25 percent other natural minerals. The mixture is poured into a mold to form either a slab or a tile, and it is heated to a temperature ranging from 1,550 degrees Celsius to 1,800 degrees C. for 24 to 26 hours. The high temperatures and the length of time align the molecules of the glass on a nanoscopic scale, which it retains upon cooling and hardening.

What are the advantages of nanostone?

1. Unique in superior whiteness, brilliant radiance and no chromatism Perfect snow white ston; Over 95 degree super glossy but gentle to eyes;

2. Zero water absorption; acid & alkaline resistance; high temperature resistance; chemical and stain resistance; be repolished as wanted;

3. Environmentally friendly , no toxin and radiation; able to be in direct contact with food;

4. Anti-bending, anti-pressure, anti-impact, perfect for kitchen countertops, dinner table tops;

5. The most popular and classic white color stone in the world; never be out-fashioned; ideal choice for decoration with the crystallized glass panel;

6. Enjoy excellent processing of various edge finishing with automatic bridge cutting machine, hand cutting machine or portable cutting machine;

What is the difference between nano stone and stone?

| Performance | ZONVE Nano Stone | Others’ Nano Stone | Marble | Granite |

| Bending strength (MPa) | >100 | 55 | 6.7-20 | 9-24 |

| Compressive strength (Mpa) | >600 | 280 | 67-100 | 100-200 |

| Moh's hardness | 8 | 6 | 3.5-4 | 6 |

| Water absorption (%) | 0.002 | 0.005 | 0.3 | 0.35 |

| Acid resistance (%) (1% sulfuric acid) | >99 | >95 | >90 | >93 |

| Alkali resistance (%) (1% sodium hydroxide) | >99 | >95 | >93 | >93 |

| Gloss | ≥97 | ≥90 | ≥85 | ≥85 |

Whats is the advantages of ZONVE?

- Price: ZONVE independently produces and owns a number of intellectual property patents;

- Yield & delivery time: 5,000 square meters of output per day; always in stock;

- Industry experience: more than ten years of relevant industry experience; flawless production process;

- Quality control: senior talents from technical department are in control of the process; perfect quality control system;

What is 3D printing nanostone?

3D Inject Printing Nanoglass is marble look Nanoglass base on Pure White Nanoglass by 3D Printing Technology. Various kinds of Natural white Marble Patterns can be made as required. It can be applied for interior and exterior floor and wall facade, column, and countertops for various kinds of commercial projects and private projects.

Why can nano stone slabs be used as kitchen countertops?

The countertop is arguably one of the most important elements of any kitchen, not just functionally but also aesthetically. It is where all the cooking action takes place. Besides, it is also the first focal point anyone notices about your kitchen whenever they look at it! This is why the choice of material for your countertop can really set the tone and voice of your kitchen's style.

Why can nano stone be used as wall and floor covering material?

The surface of the nano-stone is with high gloss and has a Mohs hardness of 8, which is comparable to stainless steel. It is more resistant to scratches and abrasions, and it is common as the main materials of ground, table and chair feet, and high heels. Compared with ordinary marble or glaze polishing, the surface of nano-stone is more transparent, smooth and delicate, and the material has a very unusual feeling.